Evaluation of the Technology for Biodiesel Production from Jatropha Curcas Oil and Acid Oil

In recent times, the world has been confronted with an energy crisis due to depletion of resources and increased environmental problems. The situation has led for search for an alternative fuel, which should be not only sustainable but also environmental friendly. Due to increase in the petroleum and the environmental concerns about pollution coming from the car gases, Biodiesel is becoming a developing area of high concern. For developing countries, fuels of bio-origin such as alcohol, vegetable oils, biomass, biogas, synthetic fuels etc. are becoming important.

The whole 5 pages article is available for download here.

Biodiesel is now mainly being produced from soybean, rapeseed, Jatropha curcas oil (JCO), Palm oil and Acid oil. Alkali base catalyzed transesterification being the most commonly used method of Biodiesel production. Optimum conditions for production of Biodiesel from JCO and Acid oil was obtained at reaction temperature of 55 ± 1 0 C, methanol to oil molar ratio of 4:1, NaOH concentration 4% for JCO and 8% for Acid oil and the reaction time of 6-8 hour. JCO contains 15% free fatty acids (FFA) and acid oil contains 78% FFA. So two step acid base catalyzed transesterification is used to reduce FFA contents, because that reduces the yield of biodiesel. The results were obtained 85% for JCO and 90% for Acid oil for one-step alkali base catalyzed transesterification and 75% for JCO and 80% for Acid oil for two step acid-base transesterification reactions.

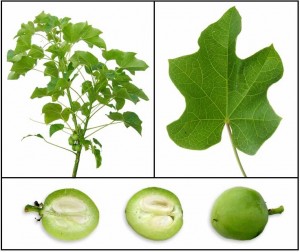

Biodiesel production is a very modern and technological area for researchers due to the relevance that it is winning everyday because of increase in the petroleum price and the environmental advantages1. Biodiesel is an eco-friendly, alternative diesel fuel prepared from domestic renewable resources i.e. vegetable oils (edible or non- edible oil) and animal fats. These natural oils and fats are made up mainly of triglycerides. These triglycerides when reacted chemically with lower alcohols in presence of a catalyst result in fatty acid esters. These esters show striking similarity to petroleum derived diesel and are called "Biodiesel". For this purpose Jatropha curcas oil and acid oil considered as most potential source for it. A variety of Vegetable oil can be used to produce Biodiesel.

These are:

Virgin vegetable oil feedstock; rapeseed and soybean oils are most commonly used, through other crops such as mustard, palm oil, sunflower, hemp and even algae show promise.

Waste vegetable oil (Refinery waste).

Animal Fats; including tallow, lard and yellow grease.

Non-edible oils; such as Jatropha curcas, neem oil, castor oil, tall oil etc.

The whole 5 pages article is available for download here.